Xilog Maestro Software Tutorial

Maestro 5 Doc. Software_Ing.indd 5 04/05/15 18:46. Tool manager The graphic representation makes tool selection direct and simple. Sector software houses The Xilog Maestro suite features the MSL Connector which allows external softwares to interface with all SCM Group’s. The MAESTRO System Software 6.0 with the MAX Programming Interface is the quickest and easiest way to program MED-EL cochlear implants. The MAESTRO System Software simplifies fittings with features designed for convenience, while MAX is a new interface that provides improved handling and connectivity.

Does anyone use an SCM Routech 125 to machine their designs from ArtCAM? My company is thinking about buying the program (we have been renting it for several months now), but there are so many issues with the post processor working with our SCM machine that we don't know if it is worth the money. (EXAMPLES of POST PROCESSOR ISSUES WE ARE HAVING: 1. We have to use a seperate program created by SCM to convert the xxl file ArtCAM creates to a pgm file which our SCM machine uses.ArtCAM should be able to do this for you.

When you watch a part being machined, the post processor makes the tools do SO MANY [i]unnecessary moves (up and down and up and down for NO REASON), it easily DOUBLES the machining time. These are SIMPLE adjustments that could be made to the post processor that will fix these issues. If anyone has any tips or at least shares our opinion on ArtCAM having MAJOR post-processor issues to work around, please let me know and we can discuss further. Possibly we can get someone to actually fix these problems in the near future if we have enough people talking about it. Does anyone use an SCM Routech 125 to machine their designs from ArtCAM?

My company is thinking about buying the program (we have been renting it for several months now), but there are so many issues with the post processor working with our SCM machine that we don't know if it is worth the money. (EXAMPLES of POST PROCESSOR ISSUES WE ARE HAVING: 1. We have to use a seperate program created by SCM to convert the xxl file ArtCAM creates to a pgm file which our SCM machine uses.ArtCAM should be able to do this for you. When you watch a part being machined, the post processor makes the tools do SO MANY [i]unnecessary moves (up and down and up and down for NO REASON), it easily DOUBLES the machining time. These are SIMPLE adjustments that could be made to the post processor that will fix these issues. If anyone has any tips or at least shares our opinion on ArtCAM having MAJOR post-processor issues to work around, please let me know and we can discuss further.

Possibly we can get someone to actually fix these problems in the near future if we have enough people talking about it. Hello DCW, 1) ArtCAM cannot output the toolpath as a *.pgm format which is a binary format but the output from ArtCAM which is *.xxl can be opened on the SCM machine which can then be converted to *.pgm machine. 2) Regarding more lift whiles actual machining, please can you let me know which ArtCAM version your program supplier is using and the parameters and settings they are using while generating the toolpath so that I can suggest you accordingly. Thanks, _________________ Chetan. We need to buy artcam for our SCM patrix CNC. I have a trial version with me. Ca you please tell me how to make a tool path for SCM CNC Machine from artcam?

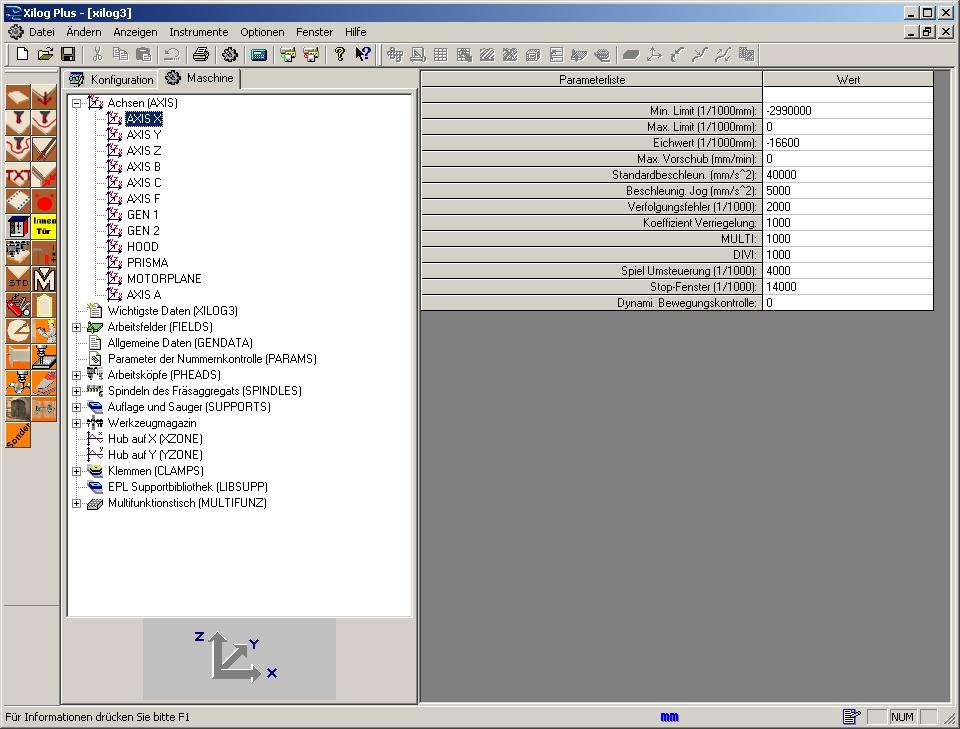

Our machine takes ISO formate. Awave studio 10 crack. But there is tool settings ( height, dia,), material settings ( suport matirial thickness,work piece thicness ) etc. I am using maestro cam/cam for programming.Have you already tried selecting the SCM Tech 25 Z Xilog (Inch) (*.xxl) or SCM Record 130-240 Xilog Plus (mm) (*.xxl) post-processor when saving your toolpaths from ArtCAM Express, and then converting the resulting *.xxl files using the WinXiso.exe application? Please confirm. Please complete any one of the tutorials included in the or and save your toolpaths using the included G-Code (mm) (*.tap) post. This outputs toolpaths in standard g-code format.

Please check if your machine accepts the saved file without any errors, and, if it does, try running your machine using it in safe conditions (dry run). If these steps do not work, you might require a custom post-processor. The cost of writing a post-processor starts at $75 US for a basic post. If you would like to move forward with a new post-processor, send an email to with the CNC type and controller; also include sample code which runs your machine.

At this point we will send further details in regards to writing a custom post-processor. Kind regards, Dillon _________________ In today's environment, hoarding knowledge ultimately erodes your power.

If you know something very important, the way to get power is by actually sharing it. Thanks for reply, I am not tried anything until now. Can you please explain how to convert.xxl file to.iso for our scm CNC?